ABOUT US

STRINGMAN GUITARS

We are Pittsburgh's go-to service for guitar and bass setups, maintenance, and repairs.

If you have lived in the Pittsburgh Tri-State area for any time at all as a guitarist or bass player, you know what kind of frustration the changes of temperature and humidity can cause with the playability of your instrument. Wood shrinks, frets sprout, necks bow, strings buzz and intonation goes wonky. With years of experience we specialize in restoring your instrument to top condition, whether it's due to seasonal changes or poor factory setup. Our services include string changes, fret repairs, setups, and mechanical upgrades inluding tuners, nuts, and bridges. We also offer electronic upgrades, such as switches and pickups, to ensure your instrument plays at its best so that you can be at your best.

PROFESSIONAL SETUP AND MAINTENANCE

String change

Fret polish

Fingerboard oil and or clean

Neck relief adjustment

String height adjustment

Pickup height adjustment

Intonation

Tremolo adjustment (if equipped)

Tuner and hardware inspection

Electronic inspection

MINOR REPAIRS AND UPGRADES

Take a Look at Our Work:

This Epiphone Les Paul Junior is a GREAT mod platform. We took a $100 used guitar and ripped all of the cheap hardware out and replaced the tuners with Kluson Classic tuners, a Graphtech nut, performed a fret level and crown, Installed a Seymour Duncan Phat Cat Humbucker sized P-90 pickup, with CTS pots and a Switchcraft output jack, and to anchor everything down, we swapped out the bridge with an intonatable Gotoh Bridge.

One of the most difficult things for players to do is setting up a Floyd Rose Bridge on an electric guitar. The ONE THING that is even harder to accomplish is setting up a D-Tuna on a Floyd Rose equipped guitar. EVH Guitars have both. With the small exception of hardtails made in the 90s and more recently the Wolfy semi hollow made for Wolfgang, Edward's Son, you get the Floyd Rose. Most folks who want their EVH guitars to play well come here to Stringman Guitars.

THE SG CLASSIC WITH A BROKEN HEADSTOCK SAGA

This poor Gibson SG met its fate while

at a music festival when another act's

guitarist borrowed it and failed to

properly return it to its stand on the stage. Yikes! We do not do finish work,

but this client was quite happy and is

still rocking this baby today!

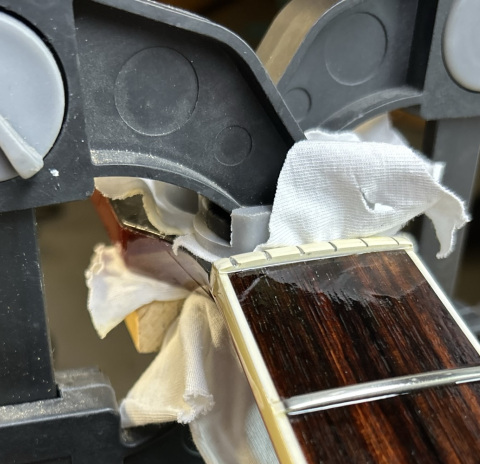

Prepping for this repair, we cleaned the

break, used a glue syringe with some

Titebond Original then clamped for 24 hours.

Here in these two pictures, you see the finished product. The repaired glue joint is stronger than the wood around it. If it suffers a similar fate, chances are it will break in a different spot. Lesson here? Don't let strangers borrow your expensive gear!

Check the two videos below!

The Video

Part 1:

The Video

PART 2:

A used Fender Kingman Acoustic Bass came in with multiple issues. The D and G strings were buzzing on the first four frets due to a nut that was cut too deep by the previous owner. We replaced the nut with a properly shaped and cut Tusq XL nut. The neck had a bow, so we adjusted the truss rod to achieve .010" relief at the 7th fret. The saddle was too high by 4/64 of an inch, so we sanded it down at the bottom to get the proper string height at the 12th fret. Additionally, we oiled the fretboard, addressed sharp fret ends, and polished the frets. Now, the bass is set up perfectly for the client, a touring musician, who brings his basses in twice a year to adjust for humidity changes in Western Pennsylvania.

Meet Ben's Schecter Bass. He bought it from a BIG BOX store. It was a BEAUTIFUL bass. Stunning top! He wanted the common upgrade of the Gotoh GB707 tuning machines, a common upgrade for bassists who want to use heavy strings for lower tunings. Unfortunately, the business that he purchased it from didn't inspect the product before shipping nor did they employ a strictly managed climate controlled warehousing system and this $600 bass had very sharp fret ends and a high third fret. Ben wanted to exchange this bass for a properly inspected and setup instrument, but this meant a three week wait as product was backordered. He brought it to our shop and we were able to level that high fret, check for others and take care of the sharp fret ends. We also installed the tuning machines, polished the frets and preformed a proper setup in D standard tuning. Ben is happy.